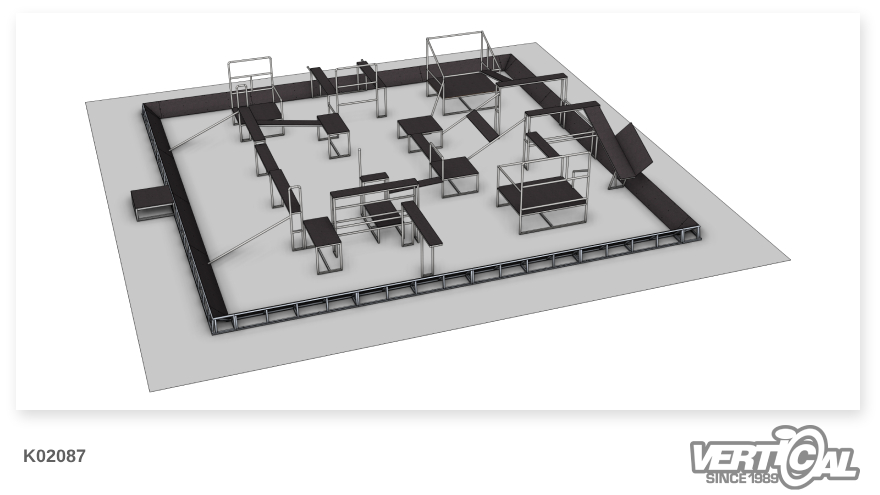

Description

Scope of delivery:

– Chase Tag system disassembled into modules

– Special steel pallets

– Tension belts, timber supports

– Assembly tools

– Documents, plans, parts lists, forms

– Assembly training

Materials:

The basic construction of the modules consists of galvanized steel tubes and pipe connectors, the edging of galvanized and welded steel tubes. Phenolic resin-coated plywood on both sides, top side with screen-printed structure, edges chamfered and painted.

Pre-assembled modules and interfaces The modules are delivered pre-assembled so that they can be transported in a space-saving manner and assembled efficiently. This saves assembly time and ensures that the individual parts are assembled correctly on the construction site.

Means of transport:

The pre-assembled modules are transported by truck. The total weight of the modules is approximately 3.2 tons. The transport dimensions on the truck are: length 9 m, width 2.4 m and height 2.6 m. A forklift with 1.8 m long forks with a minimum lifting capacity of 2 tons is required for loading and unloading the modules. The modules can only be loaded and unloaded from the side. Lifting platforms and loading a truck from the rear are not recommended.

Assembly:

At least two strong fitters and a forklift driver

are required for the assembly of the Chase Tag system (3 men in total). Duration approx. 1 day.